2016-08-12

Mechanical expansion facilitates full automation

RINGSPANN presents new disc actuated bush clamping mandrel for gearing technology

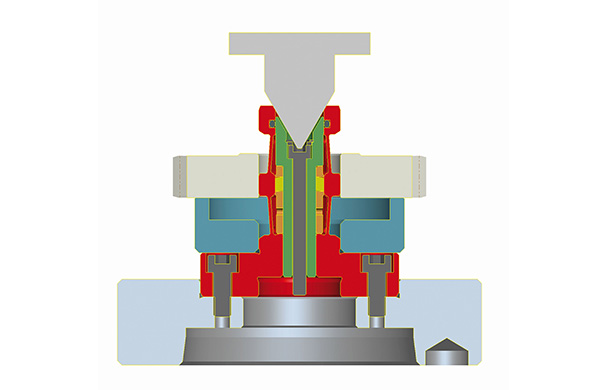

At this years’ AMB in Stuttgart, RINGSPANN will be presenting its new and now patented mechanical disc actuated bush clamping mandrel HDDS. With this product, which is a world first, metalworkers in gearing technology and fine machining get a highly precise and economically attractive alternative to hydraulic expanding clamping tools. The new RINGSPANN clamping mandrel impresses with its true running accuracy of ≤ 5 µm, can take components with bores of up to tolerance class IT10 and, in full automation, considerably reduces the expenditure for the required feeding and positioning technology. And that is by no means all!

Bad Homburg, August 2016. – With its new mechanical disc actuated bush clamping mandrel HDDS, RINGSPANN will be presenting a real cracker in the field of clamping technology at this year′s AMB in Stuttgart (13.09.16 - 17.09.16). For gear manufacturers and users in the large field of fine machining in particular, this innovative internal clamping system represents an extremely economical alternative to hydraulic expanding clamping tools. With its true running accuracy of ≤ 5 µm alone, plus the possibility of taking components with bores of up to tolerance class IT10, the new mechanical disc actuated bush clamping mandrel HDDS by RINGSPANN outperforms most hydraulic expanding clamping tools. "Hydraulic expanding clamping technology is usually only suitable for taking component bores of up to tolerance class IT7. The absolute expansion of our new disc actuated bush clamping mandrel is thus up to four times greater", stresses Volker Schlautmann, head of the clamping fixture division at RINGSPANN and inventor of the innovative internal clamping system.

Affordable route to full automation

The point made by Volker Schlautmann does not only mean a higher degree of flexibility for the user, but is particularly of central importance for the simple implementation of fully automated manufacturing concepts. Since hydraulic expanding clamping mandrels, for pure reasons of physics, have quite a small expansion rate, they require a high precision from the handling systems used for feeding. Ultimately, the lack of clearance for insertion requires an extremely high positioning accuracy, which can only be purchased through substantial extra investments in measuring and control technology. The new mechanical disc actuated bush clamping mandrel HDDS by RINGSPANN takes this worry off the user′s shoulders and clears the way for a much cheaper route to full automation.

Moreover, AMB visitors will discover, at RINGSPANN′s trade fair stand C09 in hall 2, that the new internal clamping system can also be used without any problems for workpieces with very short clamping lengths. The reason for this is also a purely mechanical one: The new disc actuated bush clamping mandrel performs a pull-back action, where the workpiece is pressed against a backstop and aligned – also ensuring an accurate centring and clamping of components with short clamping lengths. Even bores interrupted by a groove for example can be reliably and precisely taken by the HDDS from RINGSPANN without any supplementary aids.

Clamping without risk of leakage

A fundamental advantage of the new mechanical disc actuated bush clamping mandrel by RINGSPANN consists in the fact that, as opposed to hydraulic clamping systems, it is not subject to any risk of leakage. This gives the user a greater process reliability, since a leak on a hydraulic extension clamping tool always goes hand in hand with malfunctioning, disassembly from the machine and repair by the manufacturer. "If there is any wear at all with our new mechanical disc actuated bush clamping mandrel, then it is merely the clamping discs used –also quality RINGSPANN products – that are subject to minimal wear. However, these can be exchanged very easily and quickly by the user, and the HDDS does not even need to be taken from the machine spindle to do so", says factory manager Volker Schlautmann.

The new mechanical disc actuated bush clamping mandrel HDDS by RINGSPANN has already been able to prove its aptitude to some first customers in series production, in the fine grinding of teeth for example. Based on the findings obtained from this, the premium manufacturer from Bad Homburg has now started extending its standard series with this new internal clamping system for clamping diameters from 32 to 82 mm. "Through creating series of complete precision clamping fixtures, we are remaining faithful to our objective of providing RINGSPANN customers with complete clamping fixtures, finished according to their specifications in terms of clamping diameter, and supplied in the shortest time", stresses Volker Schlautmann.